Product Details

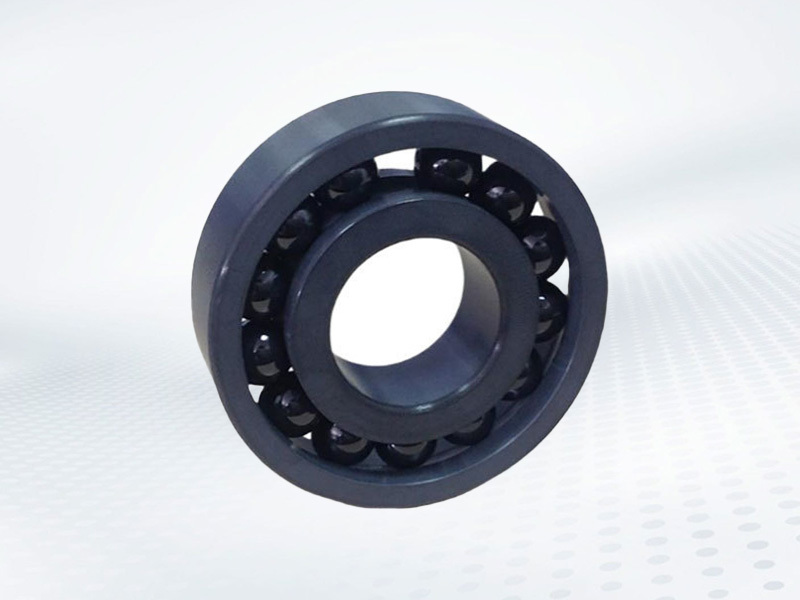

Full SiC Ceramic Bearing

Parameter characteristics

Category:

Product Details

Full SiC Ceramic BearingDimensional Table

|

Bearing Model |

Overall Dimensions(mm) |

Mounting Dimensions(mm) |

Weight (kg) (Ref.) |

|||||||||

|

d |

D |

B |

r(Min) |

da(Min) |

da(Max) |

Da(Max) |

ra(Max) |

ZrO₂ |

Si₃N₄ |

plastic |

SUS |

|

|

683 |

3 |

7 |

2 |

|||||||||

Product Features

Silicon Carbide (SiC) is a kind of inorganic non-gold corosion material, which has high hardness, strong wear resistance, low thermal expansioncoeffcient, high thermal conductivity and chemical corosion resistance. Compared with zirconia (ZrO₂)bearing material, it can be used in moreharsh corrosive environment. The silicon nitride bearing produced by Fast Company adopts the new generation of pressureless sinteredsiliconnitride (SSIC), which is made of high purity a-SIC powder and additive,and is sintered at high temperature with high purity and high density bymeans of pressureles sintering process. The hardness, strength, high temperature resistance and impact resistance of SiC, pressureless sinteredSiC without fre silicon are better than those of other engineering ceramics such as zirconia and reaction bonded silicon carbide. The siliconcarbidefullceramic bearing rings and rolling elements are made of pressureles silicon carbide (SSIC)ceramic material,and the retainer uses PTFEas the standard configuration.

Product Configuration

|

Inner And Outer Ring |

SSIC(Silicon carbide ) |

|

Cage |

PTFE ( Poly tetra fuoroethylene )、PEEK ( polyetheretherketone )、PA ( Polyamide )、UPE(Ultra-high molecular weight polyethylene)、SUS( stainless steel ) |

|

Ball |

SSlC(Silicon carbide) |

|

Seal |

Open、ZZ、2RS |

Ceramic Bearing Service Temperature And Cost

| Inner and outer rings/balls/retainers | Load Capacity | Limiting Speeds | Corrosion Resistance | Maximum Service Temperature | Cost of use |

| ZrO2/ZrO2/PA | ★★★★★ | ★★★★★ | ★★ | 90℃ | ★★★★★ |

| ZrO2/ZrO2/PTFE | ★★★★★ | ★★★★★ | ★★★★★★★ | 260℃ | ★★★★★ |

| ZrO2/ZrO2/PEEK | ★★★★★ | ★★★★★ | ★★★★★★ | 260℃ | ★★★★★ |

| ZrO2/ZrO2/PI | ★★★★★ | ★★★★★ | ★★★★★★ | 300℃ | ★★★★★★ |

| ZrO2/ZrO2/Full ball without retaining frame | ★★★★★ | ★★★★ | ★★★★★★★ | 400℃ | ★★★★★ |

| Si3N4/Si3N4/PA | ★★★★★★ | ★★★★★ | ★★ | 90℃ | ★★★★★★ |

| Si3N4/Si3N4/PTFE | ★★★★★★ | ★★★★★ | ★★★★★★★ | 260℃ | ★★★★★★ |

| Si3N4/Si3N4/PEEK | ★★★★★★ | ★★★★★★ | ★★★★★★ | 260℃ | ★★★★★★ |

| Si3N4/Si3N5/PI | ★★★★★★ | ★★★★★★ | ★★★★★★ | 300℃ | ★★★★★★★ |

| Si3N4/Si3N4/Full ball without retaining frame | ★★★★★★ | ★★★★★ | ★★★★★★★ | 800℃ | ★★★★★★ |

| SIC/SIC/PA | ★★★★ | ★★★★ | ★★ | 90℃ | ★★★★★★★ |

| SIC/SIC/PTFE | ★★★★ | ★★★★ | ★★★★★★★ | 260℃ | ★★★★★★★ |

| SIC/SIC/PEEK | ★★★★ | ★★★★ | ★★★★★★ | 260℃ | ★★★★★★★ |

| SIC/SIC/PI | ★★★★ | ★★★★ | ★ ★★★★★ | 300℃ | ★★★★★★★★ |

| SIC/SIC/Full ball without retaining frame | ★★★★ | ★★★ | ★★★★★★★ | 1100℃ | ★★★★★★★ |

Keywords:

Product parameter manual

Keywords:

Online Inquiry

Leave your contact information to get a free product quote

Our Advantages

Why Choose Us

Our Capabilities

R&D Design: Scientific design analysis through CAE software. Machining: From raw materials to finished parts. Assembly and testing: Mechanized assembly system and performance testing.

Our Quality

Each component of Xuchang Jingong balanced suspension assembly is made of high-quality domestic raw materials and processed by high-quality and highly skilled employees of Xuchang Jingong.

Our Technology

The R&D center has established a functional positioning of "strengthening platform construction, cultivating core technologies; focusing on process optimization, serving production markets; focusing on user value, and leading market demand".

Our Service

Four service systems, professional cooperation and win-win, this is Jingong Machinery's commitment to customers. Professional, systematic, and comprehensive services are essential.