Product Details

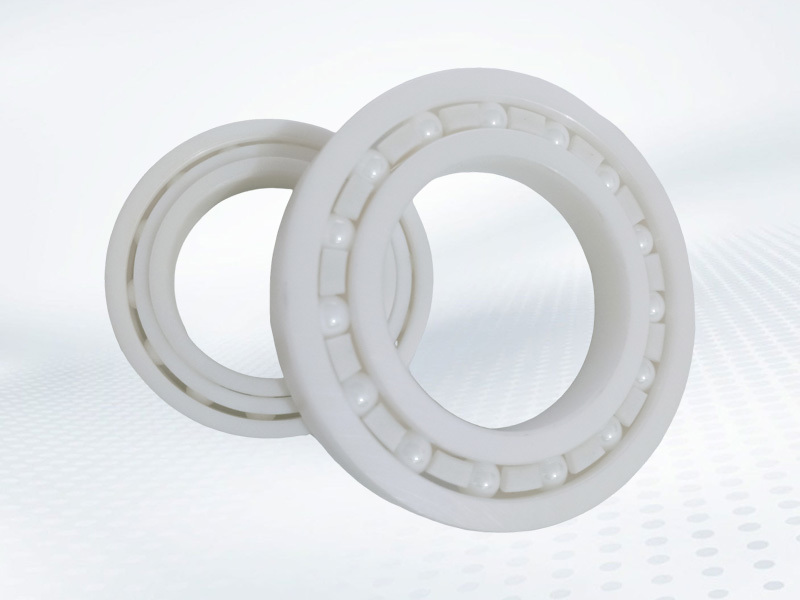

ZrO₂ Deep Groove Ball Bearing

Parameter characteristics

Product Details

ZrO₂ Deep Groove Ball BearingDimensional Table

|

Bearing Model |

Overall Dimensions(mm) |

Mounting Dimensions(mm) |

Weight (kg) (Ref.) |

|||||||||

|

d |

D |

B |

r(Min) |

da(Min) |

da(Max) |

Da(Max) |

ra(Max) |

ZrO₂ |

Si₃N₄ |

plastic |

SUS |

|

|

6301 |

12 |

37 |

12 |

1 |

17 |

18 |

32 |

1 |

0.046 |

0.025 |

0.012 |

0.06 |

Product Features

Zirconia (ZrO₂)all-ceramic bearing has the characteristics of anti-magneticinsulation,wear-resisting and corosion-resistant,oil-free self-lubrication,high temperature and cold resistance,etc.The expansion caused by temperature difference does not occur in the temperature rangeof 100℃ to 600℃ for along period of time.Can be used in strong acid,strong alkali,inorganic,organic salt,seawater and other extremely harshenvironment and special conditions,rings and rolling element using zirconia (ZrO₂)ceramicmaterials.,The protector use5(PTFE)as the standardconfguration,and can also use fberglass strong nylon66(GRPA66-25),special engineering plastics (PEK,PI),stainless steel(ASISUS316,SUS304),brass(Cu),etc.

Product Confguration

| Inner And Outer Ring |

ZRO₂ |

|

Cage |

PTFE ( Poly tetra fuoroethylene )、PEEK ( polyetheretherketone )、PA ( Polyamide )UPE(Ultra-high molecular weight polyethylene)、SUS( stainless steel ) |

|

Ball |

ZRO₂(Zirconia)、Sl₃N₄(Siliconnitride)、SSlc(Silicon carbide) |

|

Seal |

Open、ZZ、2RS |

Corrosion Resistance of Zirconia Ceramic Bearing

| Chemical Environment |

Molecular Formula |

Contents % |

Temperature | Anti-corrosion Property |

|

Acetic Acid |

CH3COOH |

|

Boiling |

Exeellent |

| Acetic Acid/Acetic Anhydride |

CH3COOH+CH3CO |

50/80 |

Boiling |

Exeellent |

|

Water+Sodium Chloride |

H2C03 |

|

Boiling |

Exeellent |

|

Carbonic Acid |

H2C03 |

|

Boiling |

Exeellent |

|

Copper |

Cu |

|

1400℃ |

Exeellent |

| Sour Food |

|

|

Boiling |

Exeellent |

|

Fruit Juice |

|

|

Boiling |

Exeellent |

|

Hydrochloric Acid |

HCL |

35 |

25℃ |

Good |

|

Hydrochloric Acid+Iron Oxide |

HCl+FaCl2 |

|

Boiling |

Good |

|

Hydrofluoric Acid |

HF |

|

25℃ |

None Resistant |

|

Nitric Acid |

HN03 |

83 |

25℃ |

Good |

|

Nitric Acid+Hydrochloric Acid |

HN03+HCL |

80+20 |

Boiling |

Good |

|

Phosphoric Acid |

H3P04 |

85 |

25℃ |

Exeellent |

|

Potassium Hydroxide |

KOH |

|

25℃ |

Exeellent |

| Sodium Carbonate+Sulfuric Acid |

Na2C03 4-H2S03 |

18/20 |

925℃ |

Exeellent |

|

Sodium Hydroxide |

NaOH |

|

Boiling |

Exeellent |

|

Sulfuric Acid |

H2S04 |

20 |

25℃ |

Exeellent |

|

Sulfuric Acid |

H2S04 |

98 |

50℃ |

Good |

|

Aluminium |

AL |

100 |

700℃ |

Exeellent |

|

Zinc |

Zn |

100 |

5000℃ |

Good |

Keywords:

Product parameter manual

Keywords:

Online Inquiry

Leave your contact information to get a free product quote

Our Advantages

Why Choose Us

Our Capabilities

R&D Design: Scientific design analysis through CAE software. Machining: From raw materials to finished parts. Assembly and testing: Mechanized assembly system and performance testing.

Our Quality

Each component of Xuchang Jingong balanced suspension assembly is made of high-quality domestic raw materials and processed by high-quality and highly skilled employees of Xuchang Jingong.

Our Technology

The R&D center has established a functional positioning of "strengthening platform construction, cultivating core technologies; focusing on process optimization, serving production markets; focusing on user value, and leading market demand".

Our Service

Four service systems, professional cooperation and win-win, this is Jingong Machinery's commitment to customers. Professional, systematic, and comprehensive services are essential.